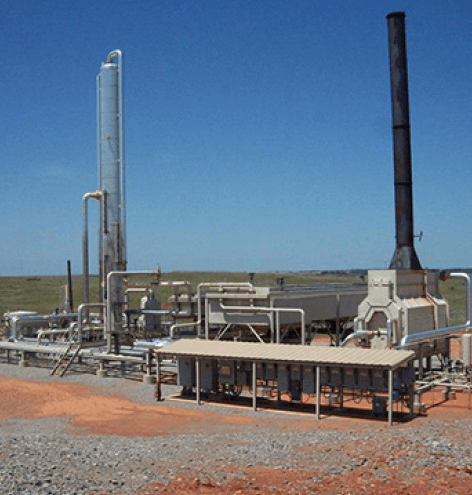

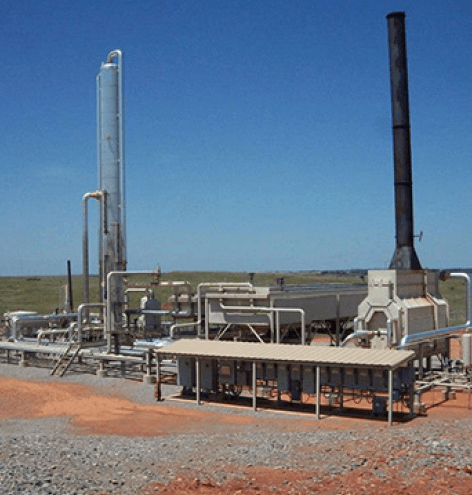

FlareCatcher Skids

a modular gas processing solution that specializes in capturing flares during upstream activities such as drilling and testing. Equipped with advanced technology, to reduces flaring, subsidies power and diesel, and captures liquids for further processing.